Embark on an odyssey through the artful and scientific realms of tobacco manufacture, a journey from seed to the symphony of flavors savored by aficionados globally. This voyage is punctuated by myriad meticulous steps, each a testament to the artisanal and precise nature of tobacco creation. Despite the swirling controversies, the undeniable mastery in its crafting beckons a closer look into this fascinating domain, celebrating the individuals whose lives are interwoven with this ancient craft.

Deciphering Tobacco’s Legacy

Straddling the realms of tradition and technological advancement, tobacco’s odyssey is a centuries-old narrative, evolving from a humble plant to a sophisticated pleasure. As a connoisseur and writer, I extend an invitation to traverse the captivating narrative of tobacco’s transformation.

Ancient Roots: Tobacco’s Timeless Saga

Spanning millennia, tobacco’s tale begins with the indigenous peoples of the Americas, where it was intertwined with spirituality and healing, far beyond its modern pleasure.

The Tobacco Plant: Nature’s Alchemy

Nicotiana tabacum, a plant of remarkable resilience and diversity, stands at the core of tobacco’s global odyssey, adaptable to the myriad tapestries of Earth’s climates.

From Soil to Splendor: The Cultivation Chronicles

The saga commences with the seed, where understanding the alchemy of soil, climate, and time is paramount in nurturing leaves of unparalleled quality.

The Harvest: A Confluence of Skill and Nature

Harvesting emerges as a testament to human dexterity, where each leaf is meticulously chosen, ensuring only the finest are embraced in the subsequent alchemy.

The Crucible of Time: Mastery in Harvest Timing

In this dance with nature, timing is sovereign, with the harvest’s moment dictating the leaf’s destiny in flavor and texture.

Curing: The Flavor’s Forge

Through the ancient arts of flue, air, and sun curing, each leaf undergoes a transformation, a metamorphosis into a bearer of distinct aromas.

Fermentation: The Flavor Deepens

Post-curing, fermentation ushers the leaves through a crucible of heat and humidity, a process where nature’s sugars mature into a deeper complexity.

Blending: The Tapestry of Tastes

In blending, the artisan’s hand weaves together diverse leaves, crafting a mosaic of flavors and strengths to satiate the spectrum of palates.

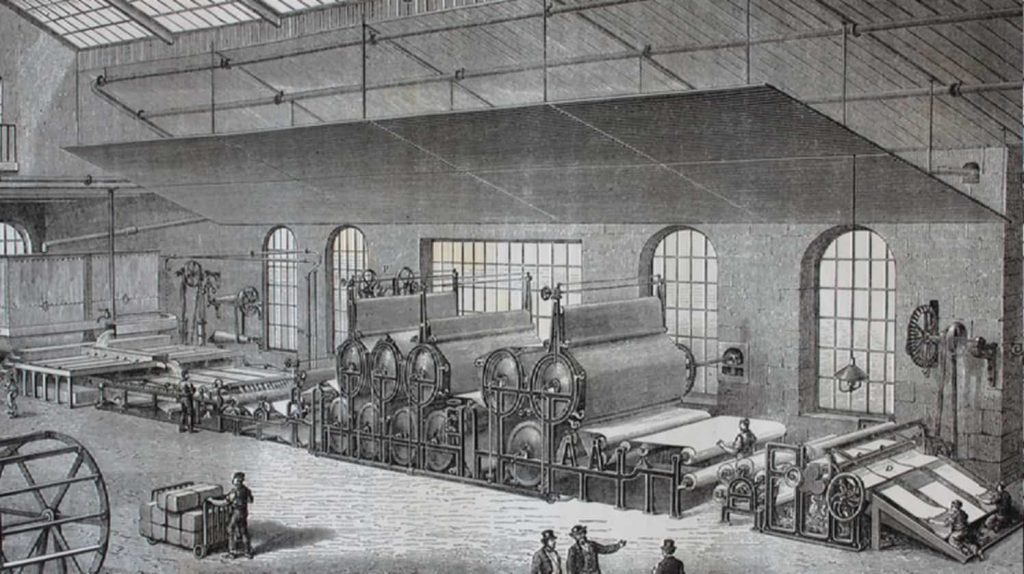

The New Age of Tobacco Crafting

Technological strides have refined, yet not supplanted, the essence of tobacco’s craft, melding the past with the present in pursuit of perfection.

The Art of the Cigar: Tradition Preserved

In the realm of cigars, the hand’s skill and soul breathe life into tradition, an art form cherished and carried forth through generations.

Excellence as Creed: The Quality Mandate

The edict of quality reigns supreme, with each offering scrutinized to uphold a legacy of excellence before it journeys to the connoisseur.

Packaging: The Final Embrace

Packaging transcends mere protection, embodying the brand’s essence and allure, a silent herald of the journey within.

The Socioeconomic Tapestry

The fabric of tobacco is interwoven with the threads of economies and cultures, a testament to its enduring legacy in human society.

Innovation’s March: Tobacco’s New Horizon

As the tobacco narrative unfolds, innovation steers its course, with sustainability and efficiency lighting the path forward.

The Core Steps of Tobacco’s Transformation

Embarking on the tobacco journey involves pivotal steps:

- Leaf and Legacy: Selecting diverse tobacco varieties and grades crafts the unique tapestry of each blend.

- Alchemy of the Leaf: The raw essence of tobacco is sculpted through mechanical and chemical ministrations, weaving the raw into the refined.

- Craft and Creation: Tobacco’s essence is then rolled, cut, and adorned with filters, encapsulating the journey in each cigarette’s embrace.

- The Essence Infused: Throughout this alchemy, substances are meticulously chosen to enhance the narrative of each brand, ensuring a unique voyage.

- The Age of Refinement: A period of aging and fermentation follows, a crucible where the leaf’s chemistry is transmuted, enriching its story.

- The Seal of Excellence: The journey is underpinned by rigorous quality control and adherence to the guardians of standards, ensuring each puff is a testament to tradition and innovation.

The Multifaceted Processes of Tobacco Manufacturing

In the realm of tobacco production, complexity abounds. Here, we unearth the layers of processes that transmute simple leaves into the final, consumer-ready products:

Virginia, Burley, and Oriental Tobacco Crafting

At the heart of tobacco’s allure lies the intricate dance of blending Virginia, Burley, and Oriental leaves. The artistry of this process is in maintaining each brand’s signature by meticulously selecting and processing the leaves. This includes a symphony of slicing, casing, conditioning, blending, cutting, and drying, culminating in the creation of cigarettes and other tobacco indulgences.

Cigarette Fabrication

The creation of cigarettes is a marvel of modern automation, where a continuous tobacco rod is birthed, encased in paper, and segmented into units. This process is not just mechanical but also involves the strategic addition of ingredients to enhance moisture, flavor, and brand identity.

Tobacco Stick Craftsmanship

In specialized centers, tobacco sticks come to life through a ballet of conditioning, slicing, drying, and flavoring, culminating in the ‘cut filler’ stage, ready for further transformation.

The Art of Cigar Making

Cigar manufacturing is a testament to patience and tradition, involving prolonged aging and fermentation of tobacco. This methodical process ensures the distinctive blend and flavor profile of each cigar, executed with precision by automated machinery.

Alternative Tobacco Production Techniques

Beyond the conventional, other methods like fire curing and flue-curing speak to the diversity of tobacco production, each tailored to produce distinct types of tobacco products.

The Daunting Challenges Confronting Tobacco Manufacturing

The tobacco industry navigates through a labyrinth of challenges, from economic to ethical dilemmas:

- Economic Hurdles: The economic terrain is treacherous, with rising costs and diminishing returns putting pressure on tobacco growers, alongside the specter of inflation.

- Labor Predicaments: The industry grapples with labor exploitation, including child labor, and the acute challenge of labor shortages, driving up production costs to unprecedented heights.

- Environmental Repercussions: The environmental footprint of tobacco cultivation is significant, with deforestation, soil erosion, and water pollution being prime concerns, alongside the opportunity cost of not utilizing arable land for food production.

- Health Concerns: Tobacco farmers face health risks from nicotine exposure and tobacco dust, highlighting the need for improved occupational health measures.

- Regulatory Battles: Navigating through a maze of tobacco legislation and public health treaties poses a continuous challenge, especially in low and middle-income countries.

- Social Dilemmas: From gender inequality to the rural exodus and the fading interest of younger generations in tobacco farming, social issues add another layer of complexity.

- Market Shifts: The dynamics of tobacco sourcing are changing, with a pivot towards regions offering lower prices, leading to significant inventory challenges.

- Adaptation to Reduced-Risk Products: The industry is also wrestling with how to align with the growing market for reduced-risk products amidst regulatory and consumer health shifts.

- Ethical Controversies: Ethical issues, including the exploitation of workers, child labor, and the ethicality of testing methods, continue to plague the industry.

Conclusion: The Future of Tobacco Manufacturing

In the ever-evolving landscape of tobacco production, a delicate dance between preserving the age-old traditions and integrating modern advancements unfolds. As we peer into the future, it becomes clear that the industry’s resilience lies in its ability to morph, ensuring the legacy of this ancient craft is carried forward into the new era.

Statistics:

Remarkably, the global tobacco sector reported a production volume nearing six million metric tons in the year 2021 alone, with China standing at the forefront of this massive output.

FAQs:

-

Who regulates tobacco product manufacturing?

Oversight of tobacco product manufacturing falls under the jurisdiction of the U.S. Food and Drug Administration (FDA), which mandates adherence to an array of federal regulations. -

What equipment is used in tobacco manufacturing?

The spectrum of equipment spans from Green Leaf Threshing machines to sophisticated Primary and Secondary processing machinery, all designed to optimize efficiency and uphold quality. -

Where are cigarettes produced?

Cigarettes are rolled and packed in manufacturing hubs scattered across the globe. -

Why is a consistent blend of tobacco important in cigarette manufacturing?

Achieving a uniform blend is pivotal for maintaining the unique flavor profile and quality that distinguishes each cigarette brand. -

How are tobacco leaves processed?

Tobacco leaves are meticulously cured, trimmed, moisturized, and dried, before being blended and packaged, ready for the consumer. -

Is automation a significant part of tobacco manufacturing?

Indeed, the realm of tobacco manufacturing has become synonymous with high-speed, automated processes. -

Can the FDA’s tobacco regulations affect manufacturing practices?

Yes, FDA-imposed regulations have a direct impact on the design, packaging, and storage of tobacco products, shaping the manufacturing landscape. -

Does tobacco manufacturing involve quality control?

Rigorous quality control measures are paramount to ensure that products meet stringent standards and are free from contamination. -

Will changes in regulations impact tobacco manufacturing equipment?

Amendments in regulations may necessitate the retrofitting or updating of manufacturing equipment to stay compliant. -

What are the steps in the cigarette production process?

The production journey encompasses shredding the raw materials, enveloping the tobacco in paper, affixing filters, and the final packaging. -

How does the FDA classify tobacco product manufacturers?

The FDA categorizes entities involved in creating, modifying, mixing, or importing tobacco products as manufacturers. -

What is the role of flavor in tobacco manufacturing?

The addition of flavorings is a crucial step to impart the desired taste profile to the final product. -

Is there a global market leader in tobacco manufacturing equipment?

Korber stands out as the global frontrunner in providing Primary tobacco processing equipment. -

How does the FDA ensure tobacco product consistency?

The FDA introduces regulations aimed at minimizing variability, thereby guaranteeing consistency across products. -

What are the challenges faced by the tobacco industry in manufacturing?

The industry navigates through a maze of challenges, from aligning with consumer expectations and shareholder demands to adhering to rigorous regulatory standards.

Books:

While no specific titles emerge in search queries, literature on tobacco manufacturing would encompass discussions on its rich history, intricate processes, sophisticated equipment, and the regulatory environment that shapes the industry.

Sources of information:

Insights into tobacco manufacturing are accessible through the digital realms of corporate giants like Philip Morris International and Korber Technologies, authoritative regulatory bodies such as the FDA, and specialized resources including Statista and various equipment suppliers in the industry.

Citations:

Authoritative insights into tobacco manufacturing can be garnered from the FDA’s official portal, offering a comprehensive overview of compliance, regulations https://www.fda.gov/tobacco-products/compliance-enforcement-training/manufacturing, alongside industry pioneers like Korber Technologies, which elucidate on the advanced equipment and methodologies employed in manufacturing https://www.koerber-technologies.com/en/products/process-equipment.